SOLUTIONS

P-K MACH®

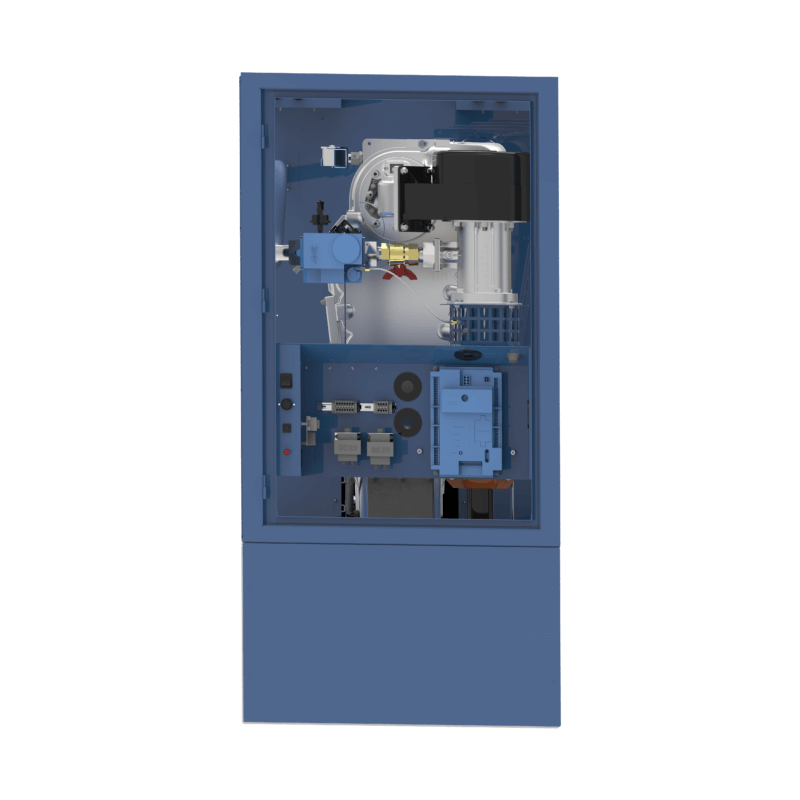

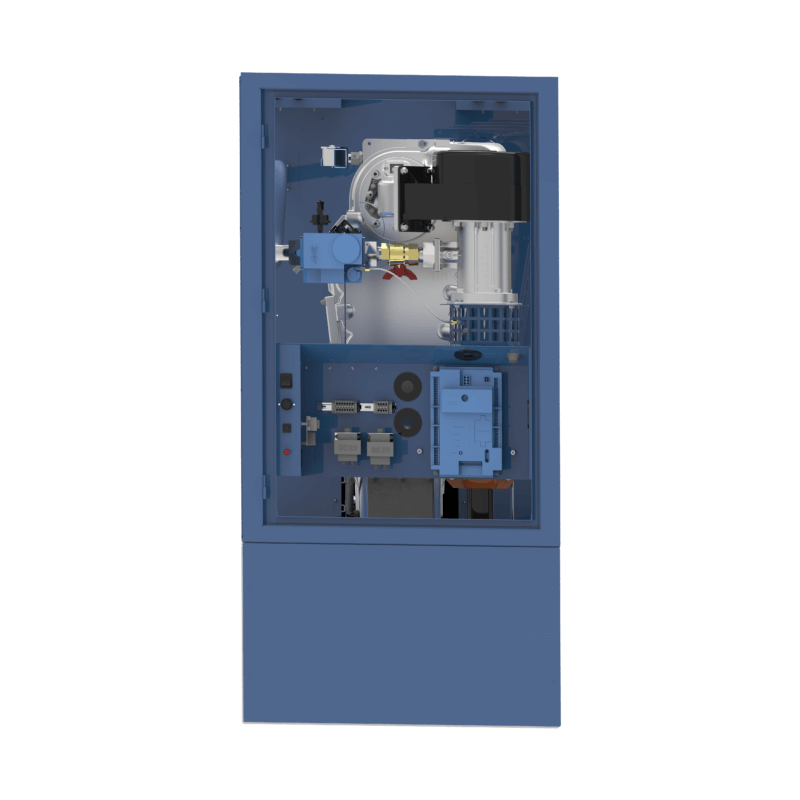

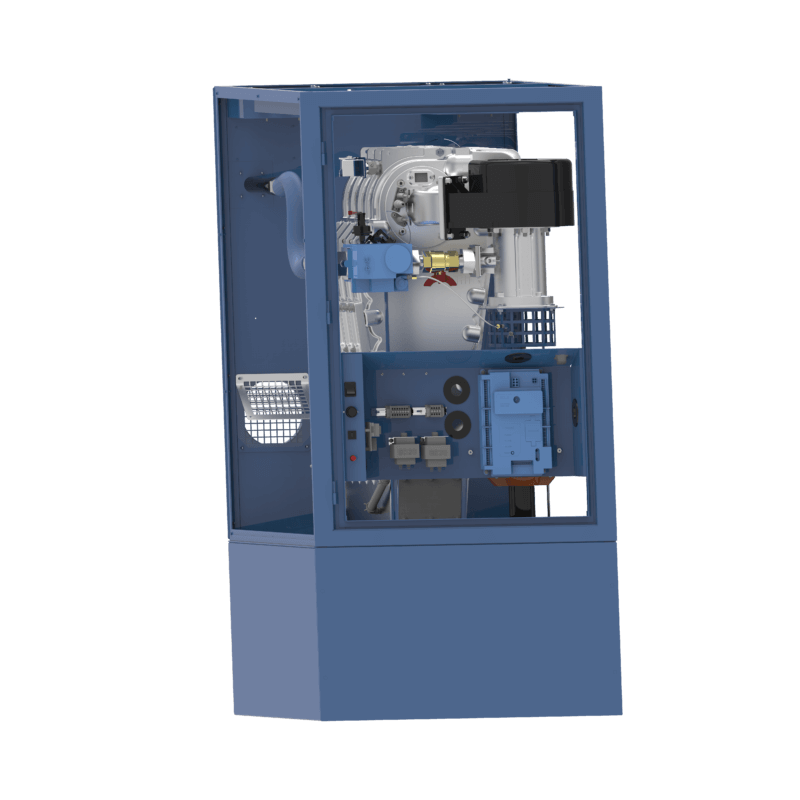

P-K MACH® Condensing Boilers

Models: CM300, CM399, CM500, C750 , C900, C1050 , C1500H , C2000H, C2500, C3000, C4000

10:1 Mechanical Turndown Now Available

Customers trust Patterson-Kelley when they need a boiler that is reliable, efficient, and constructed of quality materials!

The P-K MACH® condensing boiler is an ideal choice for a wide variety of commercial and industrial building applications, including new construction as well as retrofit projects.

Model Documents

General Documents

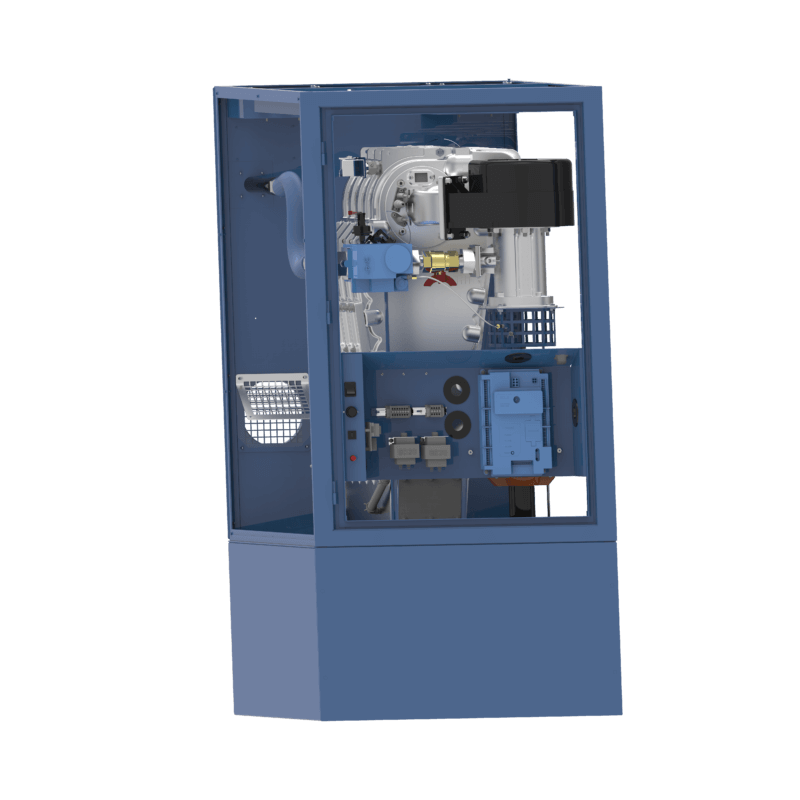

Sized to get in and fit in.

Installation time is reduced

There’s no rigging required to put your P-K MACH® condensing boiler in any room of your building, whether it’s the basement or the penthouse. All P-K MACH® condensing boilers fit through a standard 36 inch doorway or a standard elevator.

Our largest models (1,500,000 BTU/hr and larger) are equipped with wheels which means they can be moved by two people without a forklift. The narrow design of all P-K MACH® condensing boilers allow them to navigate corners and hallways with ease.

P-K MACH® aluminum boilers are perfect for new installation and retrofit projects, requiring only 4 hookups–gas, water, electric and venting.

Fire it up!

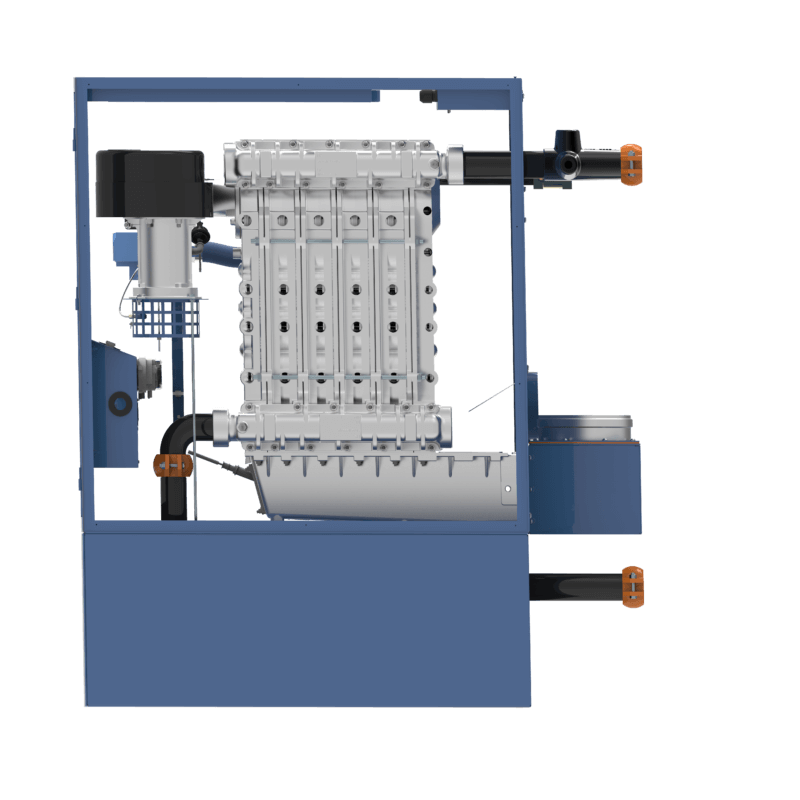

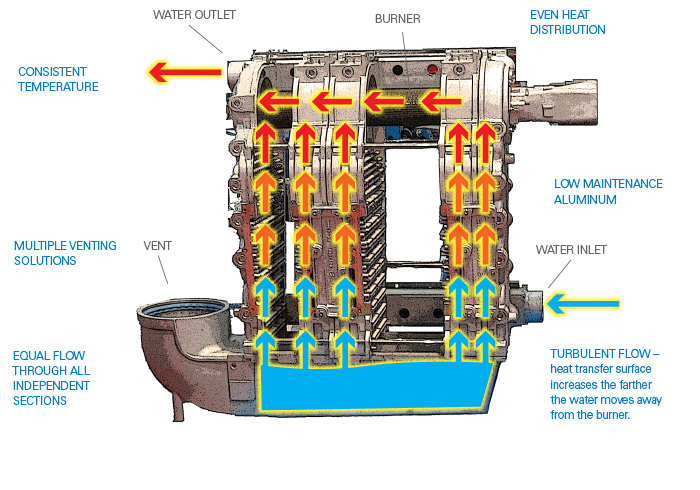

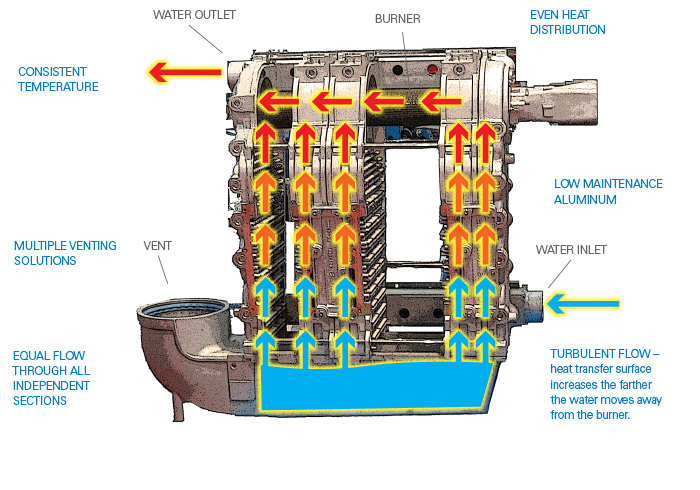

MACH® boilers feature fully independent cast aluminum heat exchangers. Since aluminum is easier to cast than other metals, the result is increased heat transfer surface for higher efficiency. The aluminum heat engine easily sheds condensate thanks to the aluminum oxide barrier that forms during use for extreme corrosion resistance.

The Aluminum Solution | Heat Engine

The heart of the P-K MACH® Condensing Boiler

P-K MACH® commercial boilers are CSA certified at 92% – 96% efficiency, with actual thermal efficiencies up to 99%.

NURO® Touch-Screen Control System

Turndown energy usage

All of our boilers are equipped with the most intuitive interface in the industry, the NURO Touch-Screen Control. Designed to maximize efficiency, the NURO Control System monitors and modulates the combustion and ignition of the boiler to maintain the desired outlet temperature.

Features:

- Actual thermal efficiency up to 99%

- All-purpose boiler suitable for condensing and non-condensing systems

- Revolutionary new, fully independent cast sectional heat exchanger

- Unique aluminum alloy resists corrosive condensate

- New boiler room layouts and control methods

- Certified low NOx performance

- Low water-side pressure drop

- Full modulation burner with 5:1 turndown

- 10:1 Mechanical turndown available on Natural Gas (NG) models C750, C900, C1050, C1500, C2000

- Variable speed combustion air blower

- Automatically compensates for changes in air temperature and pressure

- Certified at 3.5 inch Water Column minimum gas pressure

- Optional outdoor, roof, and dual fuel models

Advantages:

- A viable option for existing system retrofits and new installations

- Works well at low or high temperatures

- Simplifies construction

- Reduces overall plant life-cycle costs

- Improves comfort

- Enhances your system’s technical and economic performance

- Extremely low electrical energy consumption increases potential savings

- Dramatically improves cycle efficiencyPowerful new tool for building LEED® points

- Qualify for utility rebates

- Barely audible, even at high fire

- Actual net thermal efficiencies may be achieved up to 99%

- Water temperatures as low as 34° F