SOLUTIONS

P-K SONIC®

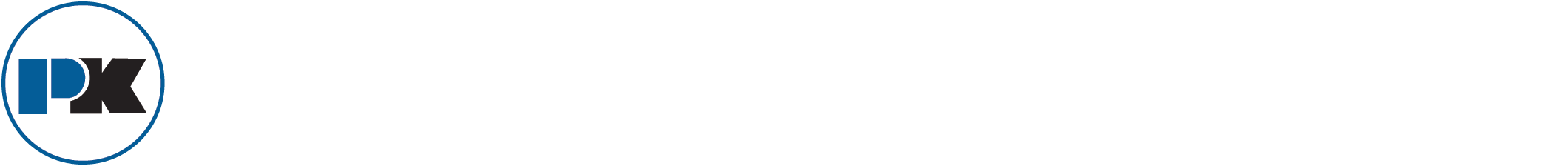

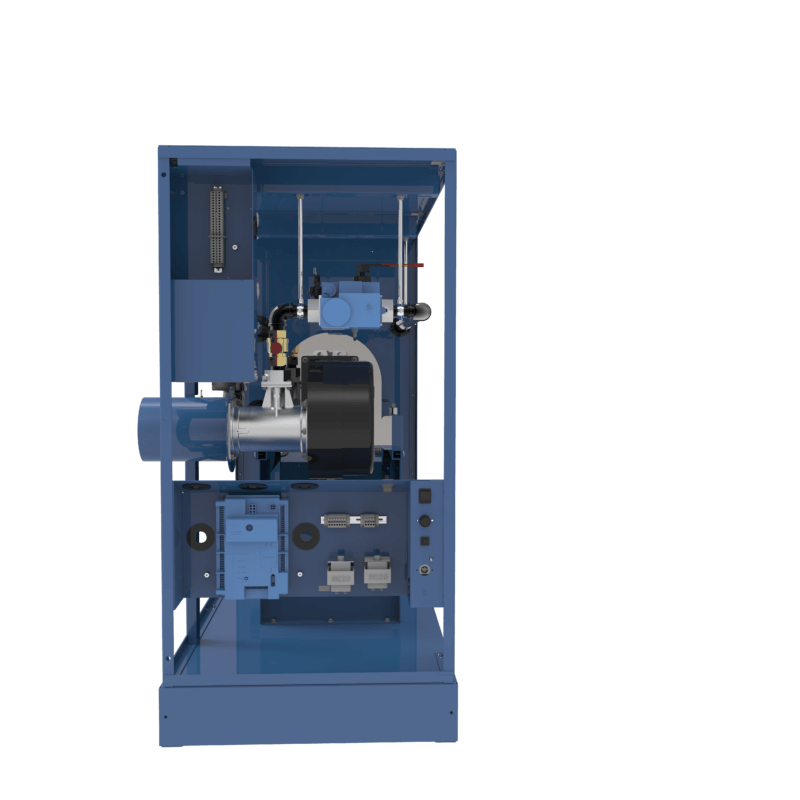

P-K SONIC® Condensing Boilers

Models: SC650, SC750, SC850, SC1000, SC1500, SC2000, SC3000, SC4000

The P-K SONIC® stainless steel, condensing boiler surpasses all expectations in efficiency, size, and material design.

Patterson-Kelley’s stainless steel boiler breaks through the limitations of all other stainless designs with sizes utilizing our revolutionary DUET™ technology. This is the industry’s first heat exchanger comprised of two unique chambers built to optimize the turndown process. Our unique heat exchanger designs allow the P-K SONIC® to operate to 97% AHRI efficiency with up to 7:1 turndown and ultra-low NOx emissions.

Model Documents

- SC3000-SC4000 Revit Drawings

- Sonic-SC3000-4000-Dual-Fuel-Revit

- SC3000 NURO LP Gas Train

- SC3000 NURO NG Gas Train

- SC3000 SC4000 NURO AutoCAD

- SC3000 SC4000 NURO Dual Fuel 240V Wiring

- SC3000 SC4000 NURO Dual Fuel 480V Wiring

- SC3000 SC4000 NURO Single Fuel 240V Wiring

- SC3000 SC4000 NURO Single Fuel 480V Wiring

- SC4000 NURO LP Gas Train

- SC4000 NURO NG Gas Train

General Documents

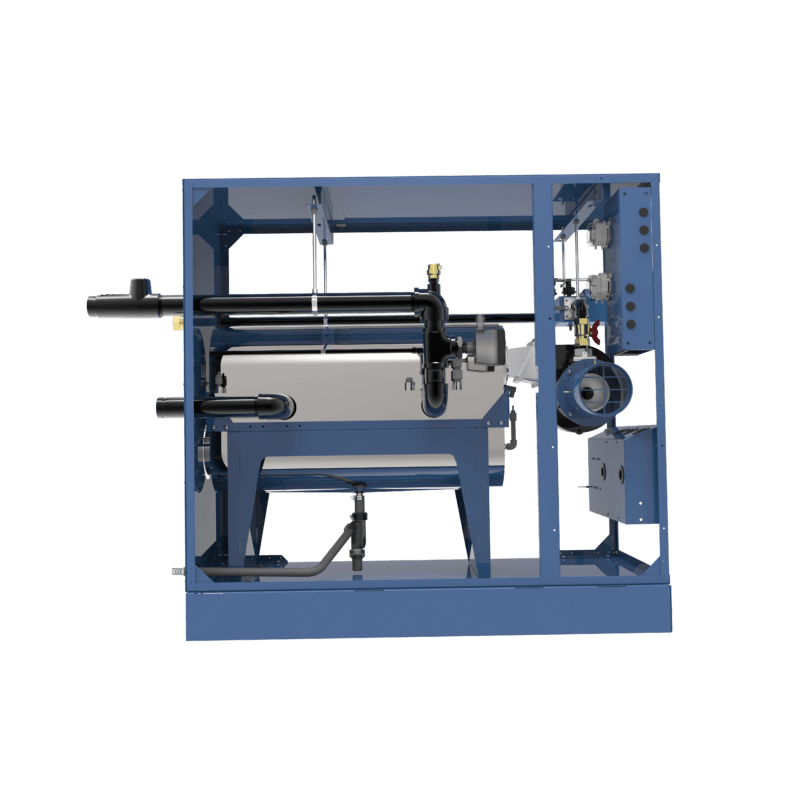

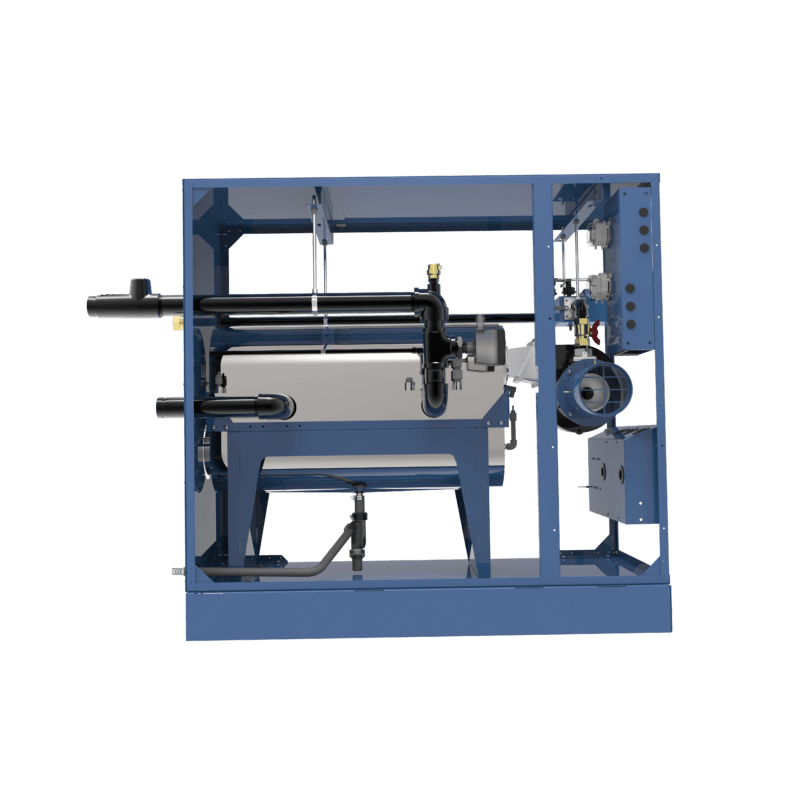

DUETTM Technology

Efficiency and harmony in design

Equipped with DUET technology, the P-K SONIC® is the premier stainless steel design for condensing applications in the industry. The innovative zones are engineered separately using different composite stainless materials that, when used together, deliver better heat transfer and higher reliability throughout the condensing process.

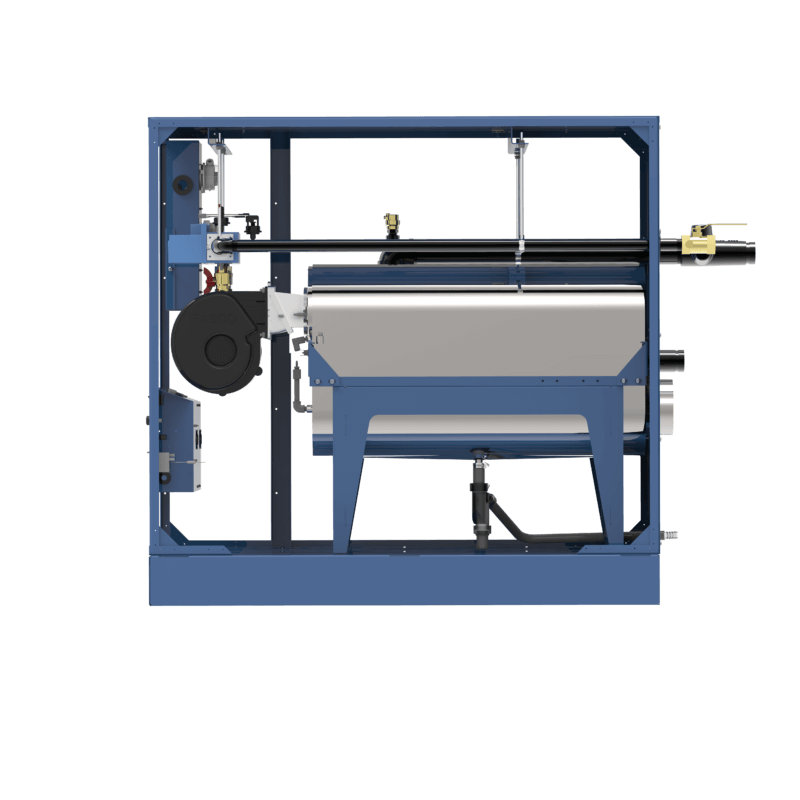

Big output in a small space

Refined engineering allows for optimal space management

In most cases, there’s no rigging required to put your P-K SONIC® condensing boiler in any room of your building, whether it’s the basement or the penthouse. All P-K SONIC® condensing boilers fit through a standard 36-inch doorway and standard elevator.

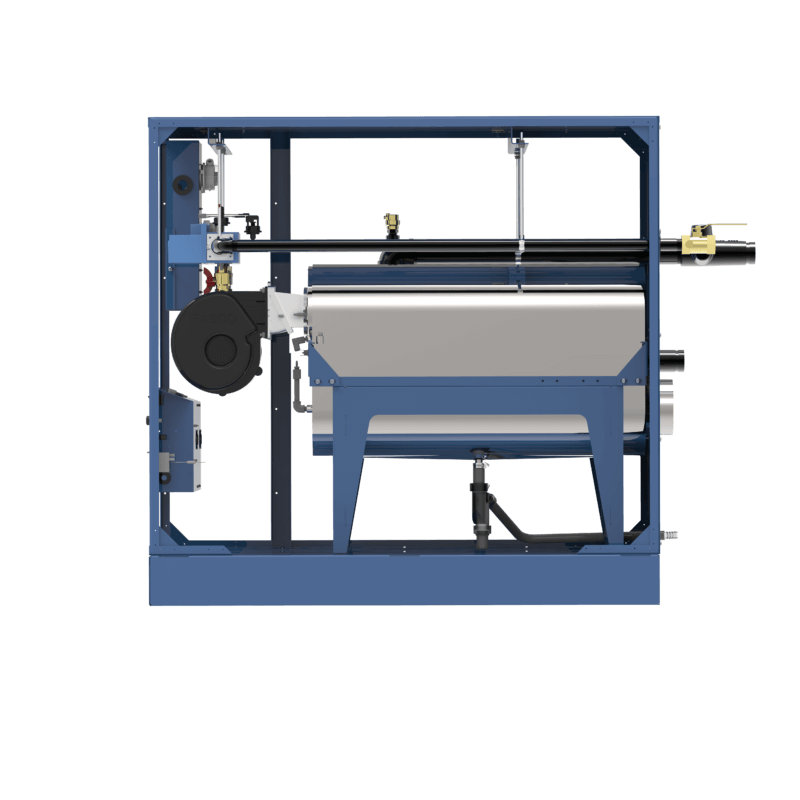

Easier to maintain

Better access and hassle-free service

The SONIC‘s clean, compact design allows internal components to be accessed with ease, saving time and money associated with repair and maintenance. Front maintenance accessibility encourages annual servicing to increase boiler life and performance.

NURO® Touch-Screen Control System

Turndown energy usage

All of our boilers are equipped with the most intuitive interface in the industry, the NURO® Touch-Screen Control. Designed to maximize efficiency, the NURO® Control System monitors and modulates the combustion and ignition of the boiler to maintain the desired outlet temperature.

Advantages

- A viable solution for existing system upgrades as well as new installations

- Innovative, high-efficiency DUET Technology

- Fits through an existing 36″ doorway

- Can be installed in a mechanical room with an 8ft ceiling

- Front accessibility reduces repair and maintenance costs and encourages annual maintenance

- Extremely low electrical energy consumption increases potential savings

- 5:1 turndown dramatically improves cycle efficiency

- Qualify for utility rebates

- Barely audible, even at high fire